We Pride ourselves on our

quick response time

We’re a first-class, no-nonsense outfit with the experience and instincts to turn a job around quickly. It’s not unusual for us to get a quote out to a prospective customer the same day we receive the request. We’ve been known to complete an entire production line, from order through installation and start-up in less than a year.

In a world where time is money we do things efficiently and we do them right the first time.

Our

Services

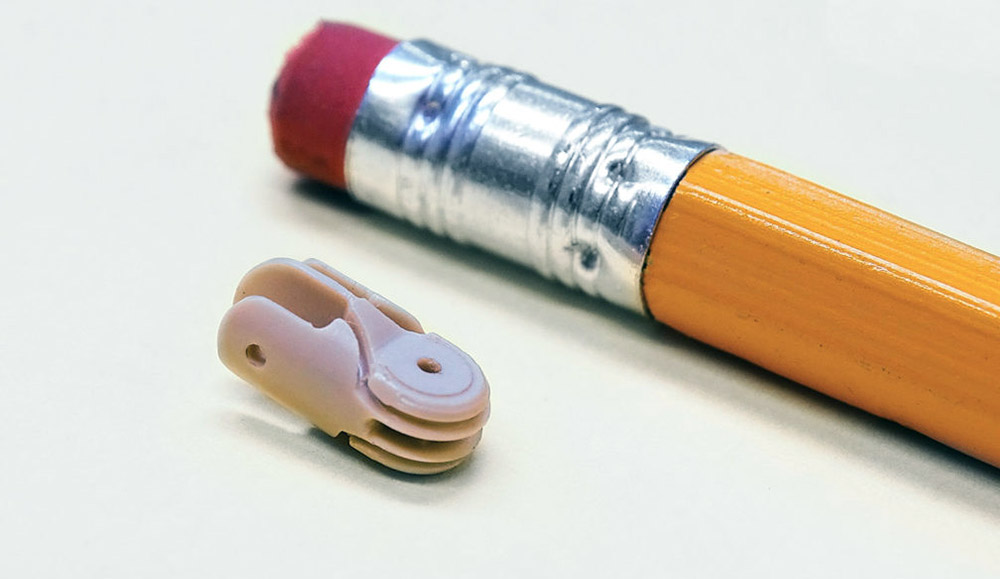

Parts large & small, we are equipped across the spectrum

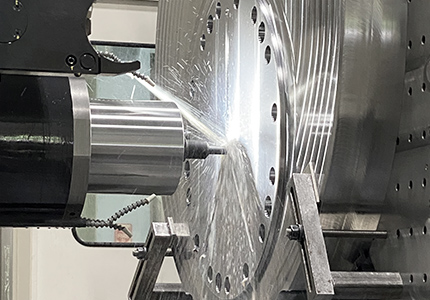

Machining &

Fabrication

We have extensive capabilities and are accustomed to producing small parts as well as fabricaitons that are massive in scale.

Wire

EDM

Using wire EDM largely alleviates the need for special tooling, saving money and lead time.

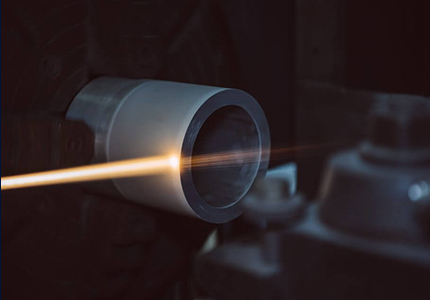

5-Axis

3D Laser

We harness the precision and speed of our CO2 laser to produce prototypes, samples, and small to mid-range runs of production lots.

Project Highlights

We have a comprehensive portfolio of projects — from precision machining close tolerance, high-value components to building complex tooling and machinery.

What Our Clients Say

“Millimeter-wave astrophysical telescopes require optics made from radio-transparent materials. For the BICEP Array, located at the South Pole, our group at Harvard University worked with Brodeur Machine to make large lenses out of polyethylene. Meeting the tight tolerances needed for our optical application with deformable plastic material is a difficult multi-step process. After a specialized optics shop turned down the job, not only did the team at Brodeur embrace the challenge, but they were also extremely flexible, responsive and efficient throughout it all. The parts were delivered ahead of schedule, and we are looking forward to working with Brodeur on the next set!”

Marion

Research Associate

Center for Astrophysics | Harvard Smithsonian

“Brodeur Machine is a strategic partner who delivers on their commitments. Their knowledge, engineering & machining spans across entire systems to ensure process needs are met at the best efficiency points. I highly recommend them based on their technical acumen, focus on service and commitment to quality.”

Shawn

Sales Manager, Delta Motor

Brodeur

Means Quality

We thoroughly examine all of our work and fully inspect all machines and components before they are sent to you.

CONTACT

Contact us directly to learn more about our comprehensive machining and fabrication services or to discuss a specific project or challenge.