We operate an integrated thermal spray coating division in our facility

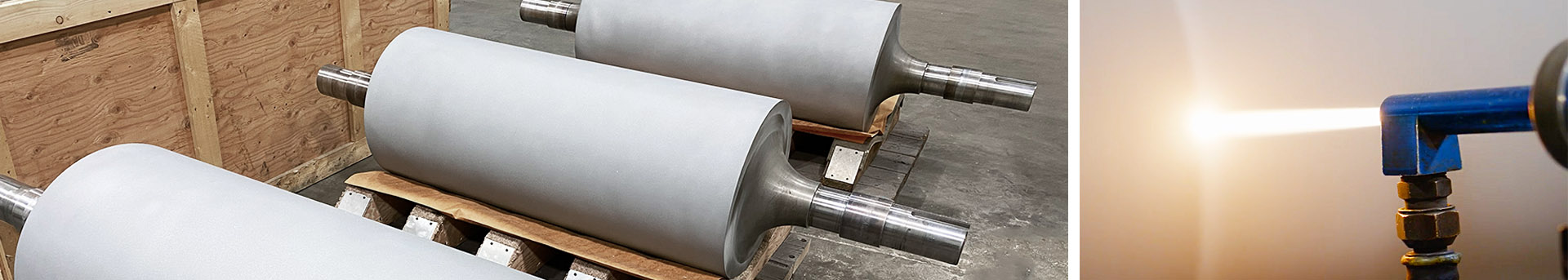

As a leading custom metal fabricator with complete build-to-print capabilities, Brodeur Machine’s thermal spray coating services excel at extending the service life of valuable components, reducing overall maintenance, and producing immediate cost savings. In fact, we operate an integrated thermal spray coating division within our Massachusetts-based facility.

Our

Expertise

Vertically Integrated Process

We can thermal spray coat almost any metal substrate. Our shop handles the entire process, from prep machining through first turning, grinding, and superfinishing.

Detailed Project Evaluations

Our coating division works closely with customers to identify the best combination of coating material for the application and the substrate, delivering specific performance characteristics at the lowest cost.

Variety of Coating Service

Our thermal spray coating can restore worn components to their original dimensions, recover mismatched mated parts, and repair incorrectly machined parts.

Durability & Performance Enhancement

We use a range of different alloy, carbide, and ceramic compositions, along with pure metals for our spray coatings. These durable options provide an effective barrier against wear, corrosion, erosion, and other surface degradation.

Performance attributes such as insulation, thermal conductivity, ESD protection, lubricity, and impact, shock, and high-temperature resistance can all be enhanced with the right thermal spray.

Our Thermal Spray Coating Equipment

Brodeur’s thermal spray application methods include HyperVelocity oxy-fuel spray (HVOF), wire arc spray, and plasma spray. Each technology offers specific benefits, depending on the coating material, the substrate, and the coating thickness applied.

HVOF Coating

This process produces coatings equivalent to or better than a detonation gun. It is used for some pure metals, alloys and carbides. HVOF gives the highest possible bond strength. The process propels gases up to 4,500 ft./sec. at 5,200° F.

Wire Arc Coating

Arc spray coating is a system in which two metal wires are fed independently into a spray gun and charged, generating an arc between them. This process is used for heavier build-up of pure metals and alloys. It propels gases up to 1100ft./sec. at 10,000 degrees F.

Plasma Spray Coating

The process consists of a non-transferred arc system. It is used principally for ceramics but has the capability to apply some pure metals, alloys and carbides. The process propels gases up to 2,000 ft./sec. at 30,000° F.

Markets We

Serve

Chemical

Petrochemical

Refining

Power

Generation

Marine

Pulp / Paper

Printing

Food

Plastics

Textile

Wire / Strip

General

Metalworking

Frequently Asked Questions

How much does spray coating cost?

The cost of spray coating can range greatly per square inch depending on the type of part, its size, its overall condition (new/used), its intended use, and more. These details help us provide the most accurate price quote.

Which thermal spray coating method is best?

The best spray coating method is entirely dependent on the end use of the part and the characteristics necessary for that use, such as conductivity, longevity, slip resistance or enhancement, etc.

What materials does Brodeur use for thermal spraying?

We can use a wide range of materials in our thermal spray coatings, including pure metals, alloys, carbides, and ceramics. Feel free to view our full list of spray coating materials here.

How long does a thermal spray coating last?

For example, thermal spray coatings can extend the life of a roll in a manufacturing operation anywhere from 3x to 15x the part life. This is specific to a rolling motion, not impact. Longevity estimates cannot be answered broadly; contact us with your specs for an accurate statement.

How quickly can Brodeur complete a thermal spray coating project?

The answer to this question depends on several factors, including the type of part, its size, its overall condition (new or used, which can determine how much prep work is needed), its intended use, and the current workload of our spray coating division.

Share some details about your thermal spray project for a custom quote and timeline. We’ll help you identify the best combination of coating material and substrate for delivering specific performance characteristics at the lowest cost.